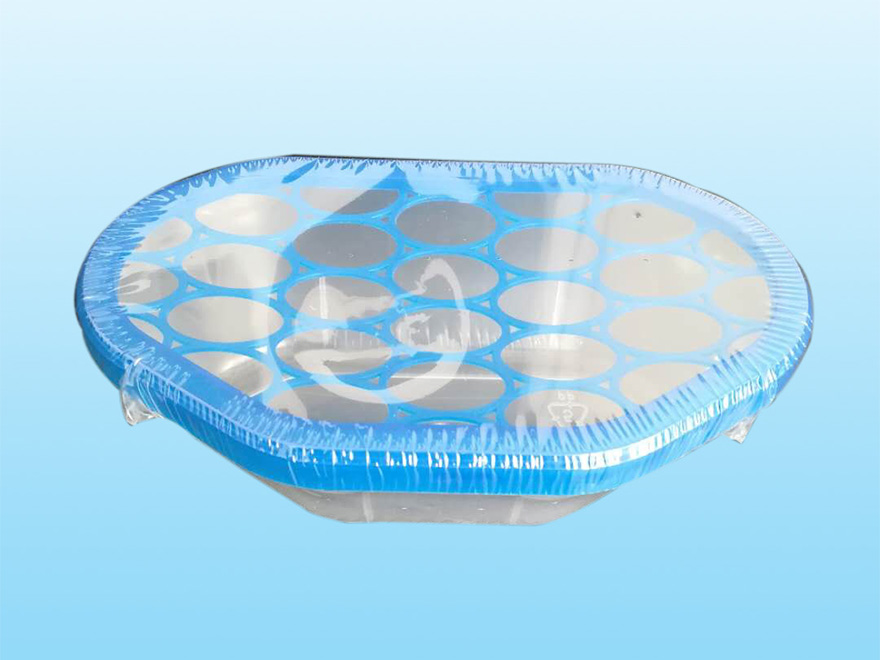

Plastic products

Description

Regarding the packing for plastic products

Heat shrinking packing with POF film are widely applied for them

Core Advantages

Flow packaging machine

3 servo PLC control more stable, smooth and accurate to run, easier to operate and more convenient to maintain.

AC motor with frequency converter to achieve Variable speed control.

Automatic feeder available for customers’ option

Safety Clutch Device to protect product from cutting, no damage of products

Linear sealing side after shrinking pack, nice and neat

Flexible packing range capable of one set of machine wrapping wide size range of products

Adopt Original Japanese technology to design with reasonable structure

Machine frame made of 12mm thickness of steel, plus further special surface-treatment to avoid deformation,anti-corrosion and can work in harsh conditions

Key components apply Japanese or German brand

With our special design, the packing film required by our machine could be narrower 20-40mm than others, which can save 5-10% film cost

The cutter made of high hardness of imported material, durable and cutting side neat

Packing data can be set via panel with memory and storage function

Self-monitor and self -diagnosis function

Packing speed:10-180pcs/minute

Machine size: 4750*965*1750MM(L*W*H)

Power supply: 220VAC/50Hz/4KW or customized

Packing material: POF

Weight: 1000KG

Distinctive heat shrinking machine

Double-layer thermal insulation, liner made of stainless steel, dual temperature control, even cyclic heating air to assure the best shrinking effect

Outer size: 2400*600*1650 mm

Inner tunnel size: 300*200*2000 mm

Weight: 400kg

Power supply: 380V/50Hz/16.2KW/3P

Applications

Suitable for packing plastic container/lid/plate/bottle and so on